Due to its flexibility, strength, and cost-efficiency, carbon steel is widely throughout different sectors. This article focuses on the characteristics, varieties, and applications of carbon steel and its relevance as the pillar of the industrial world.

Understanding Carbon Steel

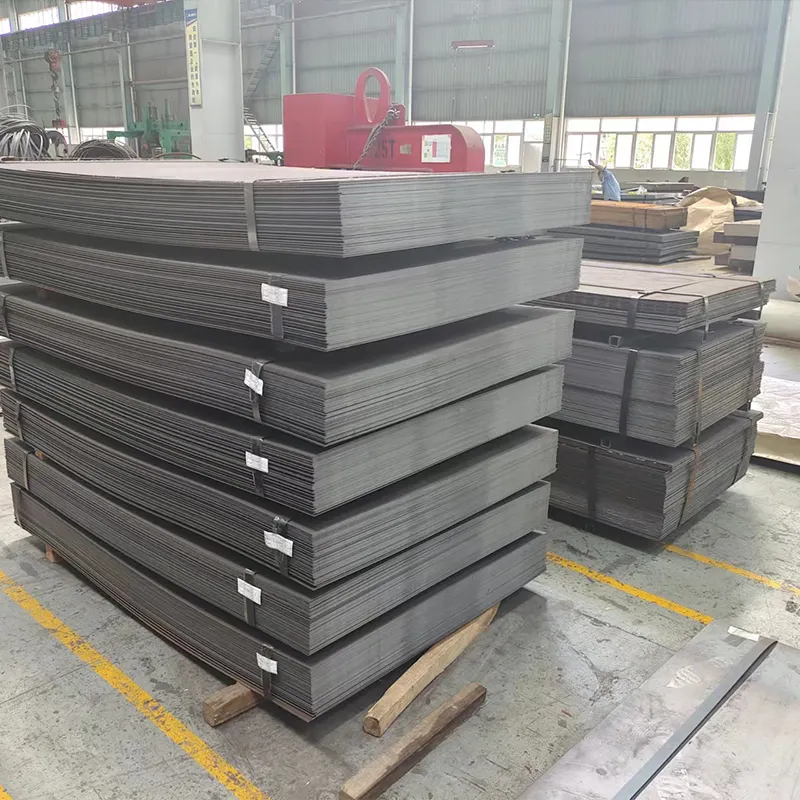

Carbon Steel is a Carbon-and iron alloy with carbon proportions varying between 0.05% and 2.0%. The material’s properties can dramatically change depending on the percentage of carbon, as it has a direct impact on hardness and strength of the steel. Steel with less than 0.3% carbon content is ductile low-carbon steel, which is ideal for use as automobile and structural components. Machinery and equipment benefit the most from medium-carbon steel, which has carbon content between 0.3% to 0.6%, due to its increased ductility and strength. Cutting tools, springs, and other high-strength applications utilize high-carbon steel, which has a carbon content between 0.6% to 2.0%.

Uses of Carbon Steel

Carbon steel has a wide range of uses. In the construction industry, it is applied to beams, columns and reinforcements due to its high tensile strength. In manufacturing, carbon steel is needed in the production of machine parts, tools, and automotive components. Its capability to endure high stress and impact makes it favorable for heavy duty applications. Moreover, carbon steel is extensively applied in the oil and gas industry for pipelines and drilling apparatus where strength and resistance to wear is fundamental.

Advantages of Carbon Steel

One of the primary advantages of carbon steel is affordability. In comparison to other alloys, carbon steel is much cheaper to manufacture, which is appealing to most fabricators. In addition, its mechanical properties can be modified by heat treatment processes, allowing for the enhancement of the strength and hardness and tailoring them to suit different applications. Carbon steel excels in weldability which is very important in construction and manufacturing processes.

Considerations and Challenges

Carbon steel is exceptionally beneficial, as just stated, but it also presents some challenges. One of the chief concerns is the risk of oxidation and corrosion, particularly in places with moisture and chemicals. In order to avoid this, chemicals protective coatings or treatments are applied. Furthermore, carbon content can also alter the steel's brittleness, which must be monitored throughout production processes so that critical use scenarios do not lead to failure.

Future Carbon Steel Trends

With the growth of industries, the application and technology related to carbon steel also grows. Continuous evolution in metallurgy is causing the emergence of new carbon steel with higher strength-to-weight ratios and other critical engineering requirements. There is also increased attention in the circular economy that promotes the use of carbon steel due to the low carbon emissions during its production. In addition, the usage of carbon steel in smart manufacturing is also increasing for better productivity and less waste in the industry.

To summarize, carbon steel is, and will always be, the backbone of industrial materials due to its unique combination of strength, elasticity, and low cost. As time goes on, new technologies emerge, which will expand its applications even more.