Corrugated Roofing Sheets

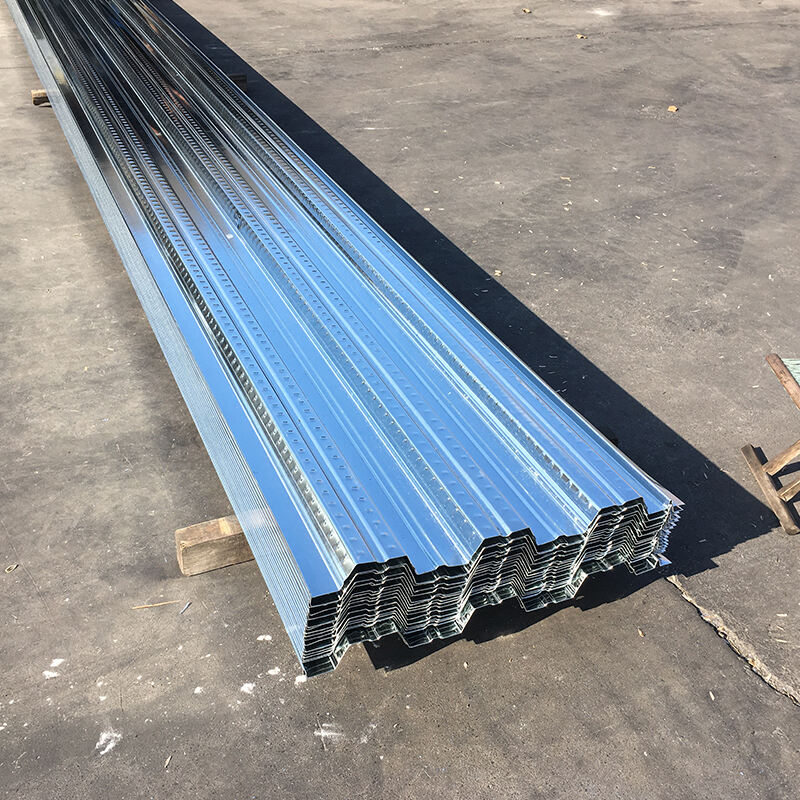

Corrugated roofing sheets are wave-shaped panels made from hot-dip galvanized steel sheets as the base material, processed through a pressing technique, and coated with a layer of zinc to prevent rust. They offer excellent corrosion resistance and mechanical strength, making them widely used in construction, industry, agriculture, and more.

- Overview

- Recommended Products

Product Overview: Corrugated Roofing Sheets

Corrugated roofing sheets are wave-shaped panels made from hot-dip galvanized steel sheets as the base material, processed through a pressing technique, and coated with a layer of zinc to prevent rust. They offer excellent corrosion resistance and mechanical strength, making them widely used in construction, industry, agriculture, and more.

Specifications and Parameters:

| Base Material | High-quality hot-dip galvanized steel sheets ensure the durability and reliability of the product. |

| Thickness | Ranges from 0.45mm to 1.2mm, customizable to meet various engineering requirements. |

| Zinc Coating Weight | 40g/m² to 275g/m², providing different thicknesses of zinc coating to meet various corrosion protection needs. |

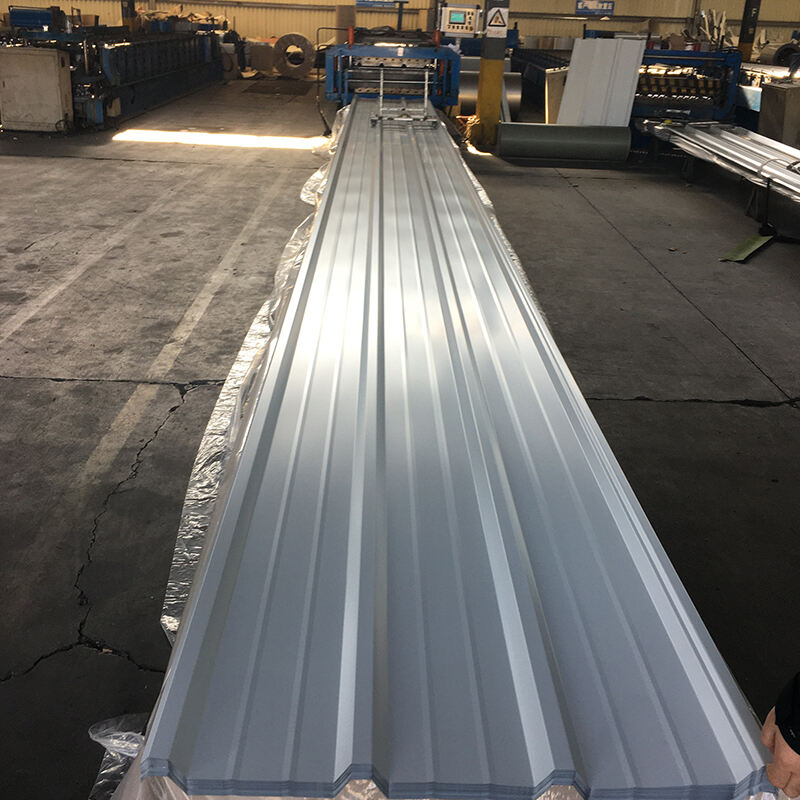

| Dimensions | Length can be customized according to customer requirements, with a standard width of 600mm to 1250mm. |

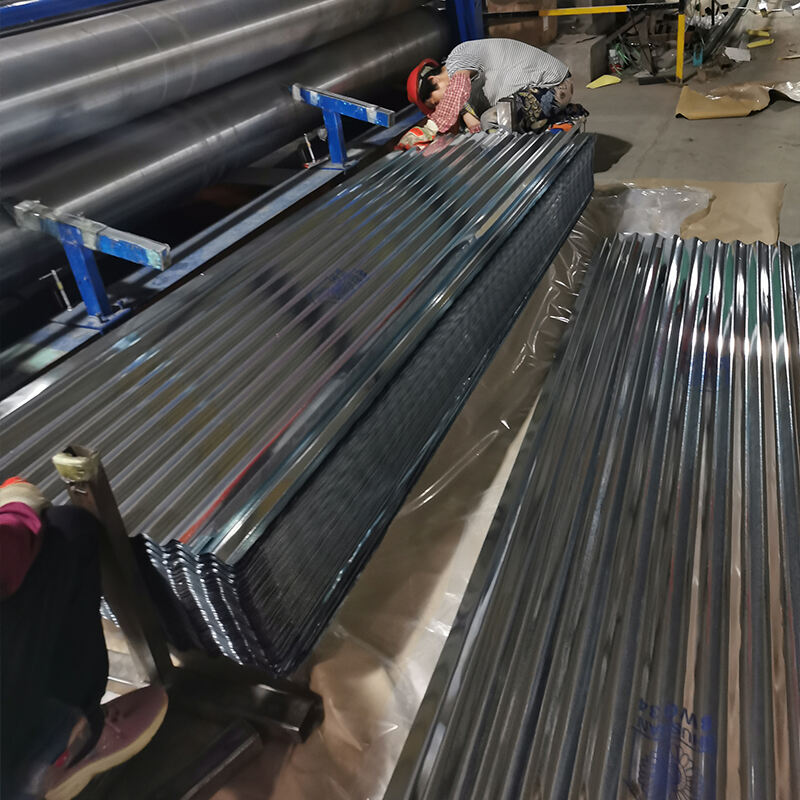

| Coating Process | Various surface treatment processes are available, such as hot-dip galvanizing and electro-galvanizing, to enhance corrosion resistance. |

Product Features:

Aesthetic Design: The wave-shaped design is simple and beautiful, suitable for various architectural styles.

Cost-effectiveness: Ensures quality while optimizing costs, providing a reasonable choice for project budgets.

Durability: Outstanding corrosion resistance allows it to withstand harsh environments and has a long service life.

Easy Processing: Easy to cut and install, can be processed on-site to meet different construction requirements.

Application Scenarios:

Construction Engineering: Used as roofing and wall materials for buildings, providing good waterproofing and thermal insulation performance.

Industrial Manufacturing: Suitable for the roofs and walls of industrial plants and warehouses, enhancing the protective performance of buildings.

Agricultural Facilities: Ideal for greenhouses, livestock breeding sheds, and more, providing protection for agricultural production.

Frequently Asked Questions (FAQ):

Q: What is the delivery time for corrugated roofing sheets?

A: The delivery time is usually 1 to 2 weeks, depending on the order quantity and processing complexity.

Q: Can corrugated roofing sheets be used in projects under extreme environmental conditions?

A: Yes, our corrugated roofing sheets are designed to withstand extreme environmental conditions, including high temperatures, cold, strong winds, and corrosive atmospheres.

Q: Are there color options for corrugated roofing sheets?

A: The standard product is silver-white, but surface painting can be done according to customer requirements, offering a variety of color choices.

Q: How should corrugated roofing sheets be maintained and cleaned?

A: Regular cleaning with a soft cloth and water is recommended. Avoid using corrosive cleaning agents to maintain the appearance and performance of the sheets.

Q: Do you provide processing services?

A: We offer basic processing services such as cutting and pressing, and can also perform special processing according to customer needs.

Contact Us:

Looking for the right corrugated roofing sheets for your project? Contact us now to get professional advice, detailed quotes, and considerate service. Our professional team is looking forward to cooperating with you.

Email: [email protected]

Phone: +86 18369600176

Choose our corrugated roofing sheets to add strength and protection to your project – where quality and reliability coexist.