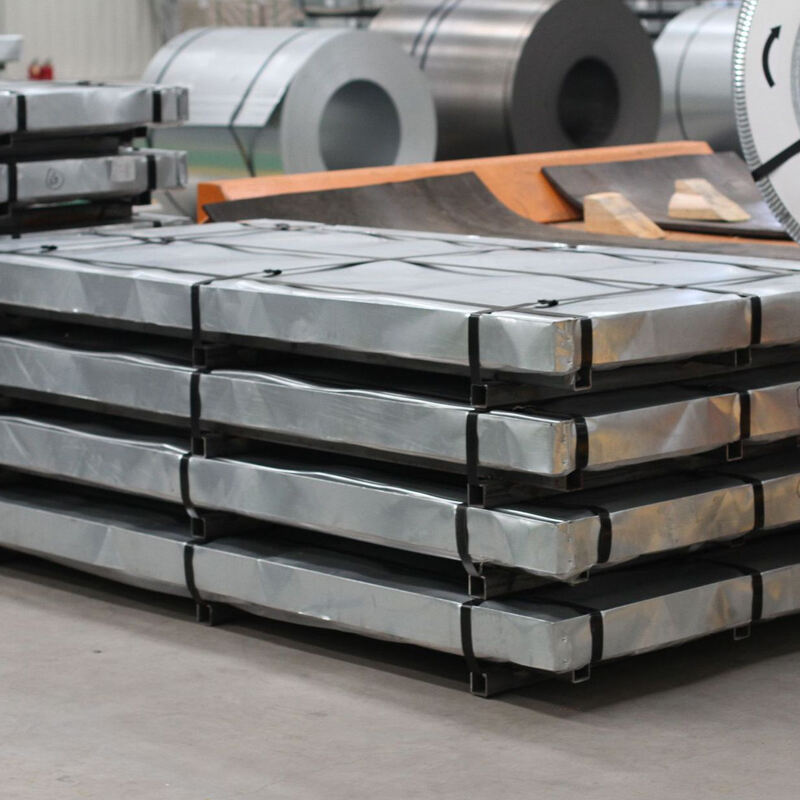

Galvanized Sheet

Galvanized sheet is a galvanized steel plate, which uses high-quality cold-rolled or hot-rolled steel plate as the substrate, and a layer of zinc is plated on the surface to enhance corrosion resistance. Galvanized sheet has different thickness and specifications, widely used in construction, machinery, home appliances, automobiles and other industries.

- Overview

- Recommended Products

Product Overview: Galvanized sheet

Galvanized sheet is a galvanized steel plate, which uses high-quality cold-rolled or hot-rolled steel plate as the substrate, and a layer of zinc is plated on the surface to enhance corrosion resistance. Galvanized sheet has different thickness and specifications, widely used in construction, machinery, home appliances, automobiles and other industries.

Specifications and Parameters:

| Material | High quality cold rolled or hot rolled steel sheet, galvanized |

| Thickness | 0.12mm-3mm, can meet the strength requirements of different application scenarios |

| Width | 600mm-1250mm, suitable for a variety of production processing technology |

| Zinc layer weight | 30g/m²-275g/m², can be customized according to anti-corrosion requirements |

| Surface treatment | Passivation, oil coating, phosphating and other surface treatment methods can be selected |

| Size | Customizable size to fit specific project specifications |

| Compliance | In line with ASTM, GB, JIS and other domestic and foreign standards |

Product Features:

Corrosion resistance: The galvanized layer forms a dense protective film, which effectively prevents the steel plate from rusting and extends the service life

High strength: After cold rolling or hot rolling process, with good mechanical properties, can withstand large loads

Aesthetics: Flat and smooth surface, can be painted in a variety of colors and patterns, improve the appearance of the texture

Machinability: Easy to cut, weld and form, convenient for a variety of complex processing operations

Environmental protection: The galvanizing process adopts environmental protection technology, and the products can be recycled, which is in line with the concept of sustainable development

Cost effectiveness: While providing excellent performance, it has a high cost performance ratio and reduces project costs

Application Scenarios:

Construction industry: Suitable for roof, wall, canopy and other building peripheral structure, to provide protection and decorative functions

Manufacturing: Used to manufacture various mechanical parts, home appliance shell, auto parts, etc., to enhance product durability

Infrastructure: It can be used in the construction of Bridges, highway guardrails, communication towers, etc., to ensure the stability of infrastructure

Agriculture and animal husbandry: Build greenhouses, breeding stalls, etc., to create a good production environment

Home decoration: Make storage shelves, decorative boards and other household items, both practical and beautiful

Frequently Asked Questions (FAQ):

Q: How long is the lead time for custom galvanized sheet orders?

A: Delivery time is generally 2 to 6 weeks, depending on order volume and processing complexity.

Q:Can galvanized sheet be used outdoors for a long time?

A: Yes, galvanized sheet has excellent weather resistance, can be used outdoors for a long time, resistance to ultraviolet radiation, rain erosion and temperature changes and other natural environmental factors.

Q: What surface treatment options are available for galvanized sheets?

A: We offer a variety of surface treatments, such as passivation treatment to improve corrosion resistance; Oil coating can prevent rust and increase lubricity; Phosphating can enhance the binding force of steel plate and coating to meet the needs of different customers.

Q: How to clean and maintain galvanized sheet?

A:The cleaning of galvanized sheet is relatively simple. Under normal circumstances, the surface dust can be removed by rinsing with water. For stubborn stains, you can use a neutral cleaner with a soft cloth to wipe, and then rinse with water. Avoid the use of strong acid and alkali detergent, so as not to damage the galvanized layer.

Q: Can the thickness of galvanized layer be customized?

A: Yes, we can customize galvanized layers of different thickness according to the specific anticorrosion requirements of customers, and the weight of zinc layers can be achieved from 30g/m² to 275g/m².

Q: Do you offer processing services?

A: We not only provide galvanized sheet materials, but also can cut, punch, bend and other processing services according to customer needs, and can also recommend professional processing partners to ensure that galvanized sheet can meet your project installation requirements.

Contact Us:

Want to choose the right galvanized sheet for your project? Contact us today for professional advice, detailed quotes and attentive service. Our team of professionals look forward to working with you.

E-mail: [email protected]

Tel:+86 18369600176

Choose our galvanized sheets to add robustness and protection to your projects - where quality goes hand in hand with reliability.