PPGI/PPGL

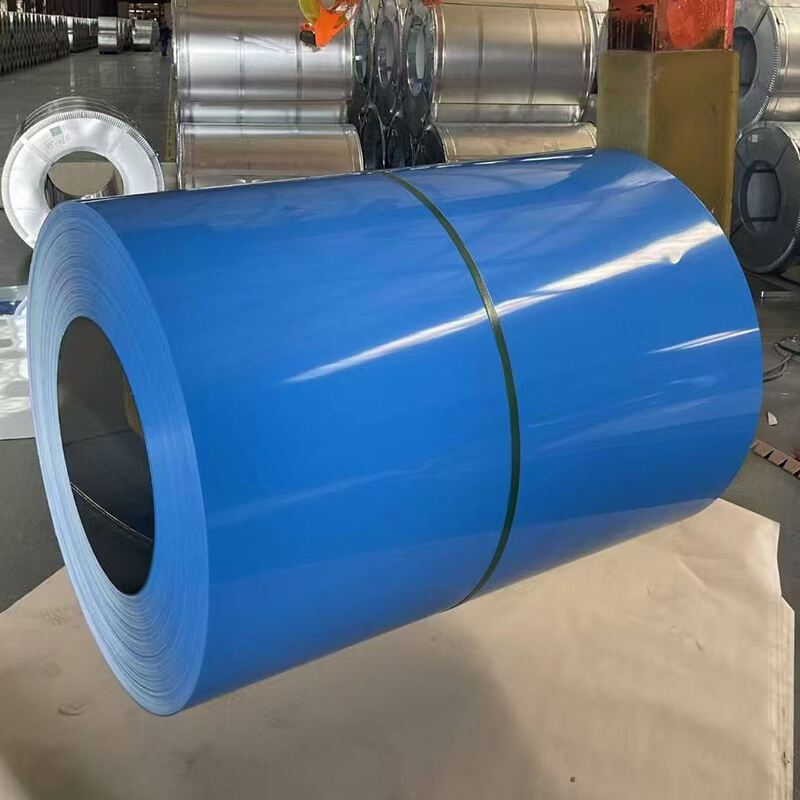

PPGI coil is short for pre-coated galvanized steel coil, which uses hot-dip galvanized steel sheet as the base material and is coated with several layers of organic coating to prevent rust. Color coated galvanized steel coil has different materials and specifications, widely used in advertising, construction, electrical appliances and other fields.

- Overview

- Recommended Products

Product Overview: PPGI/PPGL

PPGI coil is short for pre-coated galvanized steel coil, which uses hot-dip galvanized steel sheet as the base material and is coated with several layers of organic coating to prevent rust. Color coated galvanized steel coil has different materials and specifications, widely used in advertising, construction, electrical appliances and other fields.

Specifications and Parameters:

| Substrate | Selected high-quality cold-rolled or hot-dip galvanized steel sheet to provide a solid foundation for the product |

| Thickness | 0.13-0.70mm, flexible customization to meet different engineering needs |

| Color presentation | Covers a wide range of RAL standard colors, and can be customized according to customers' unique ideas |

| Coating process | PVDF, PE, SMP, HDP and other coating options to meet different performance requirements |

| Thermal insulation | Excellent thermal performance, effectively maintain indoor comfortable temperature, reduce energy consumption |

| Size customization | According to project design, precise cutting, to achieve seamless docking |

| Standard certification | Atrictly follow ASTM, JIS, EN, DIN, GB and other international and domestic authoritative standards |

Product Features:

Exterior design: A variety of colors and patterns are selected to add fashionable elements to the exterior of the building and enhance the overall beauty.

Cost-effectiveness: Under the premise of ensuring quality, achieve cost optimization and escort the project budget.

Durability: Excellent corrosion resistance and anti-aging ability, not afraid of the test of natural environment, lasting as new.

Environmentally friendly: The products can be recycled, the production process pays attention to environmental protection, and helps sustainable development.

Easy processing: good processing performance, easy to shear, stamping, bending and other operations, to adapt to the changing processing needs.

Application Scenarios:

Architectural engineering: As a building exterior wall, roof material, to create a beautiful and practical building appearance, enhance the urban landscape.

Industrial manufacturing: used for the enclosure structure of industrial plants, warehouses and other buildings, as well as the shell manufacturing of various industrial equipment to enhance the protective performance.

Home appliance industry: Used in the production of appearance parts of home appliance products, such as refrigerators, washing machines, etc., to improve product quality.

Transportation: Suitable for the interior and exterior decoration of vehicles such as cars and trains, to achieve the dual effect of lightweight and beautiful.

Advertising media: The production of large billboards, signage, with bright colors and eye-catching patterns to attract public attention, enhance advertising communication.

Frequently Asked Questions (FAQ):

Q: What is the lead time for custom PPGI/PPGL color coated coil orders?

A: Delivery time is usually 1 to 2 weeks, depending on order volume and processing complexity.

Q: Can PPGI/PPGL color coated coils be used in projects under extreme environmental conditions?

A: Yes, our PPGI/PPGL color coated coils are designed to withstand extreme environmental conditions, including heat, cold, strong winds and corrosive atmospheres.

Q: Do PPGI/PPGL color coated coils have color options?

A: Of course! We offer a wide range of RAL standard color options and can also tailor special colors to your specific needs to meet your design requirements.

Q: How do I maintain and clean PPGI/PPGL color coated coils?

A: Our PPGI/PPGL color coated coils are easy to maintain. Regular cleaning with a mild cleaner and water will keep it looking like new. Avoid abrasive cleaners to prevent scratching.

Q: What are the benefits of coatings on PPGI/PPGL color coated coils?

A: PPGI/PPGL color coated coils are coated with excellent corrosion resistance, weather resistance and decorative properties. PVDF coating also has long-term color retention and UV resistance, which can effectively extend the service life of the product.

Q: Do you offer processing services?

A: Although we mainly supply PPGI/PPGL color coated coil, we can provide cutting, stamping, bending and other processing services, and can also recommend professional processing partners to ensure that the product meets your installation requirements.

Contact Us:

Want to choose the right PPGI/PPGL for your project? Contact us today for professional advice, detailed quotes and attentive service. Our team of professionals look forward to working with you.

Email: [email protected]

Phone: +86 18369600176

Add robustness and protection to your projects with our PPGI/PPGL - where quality goes hand in hand with reliability.