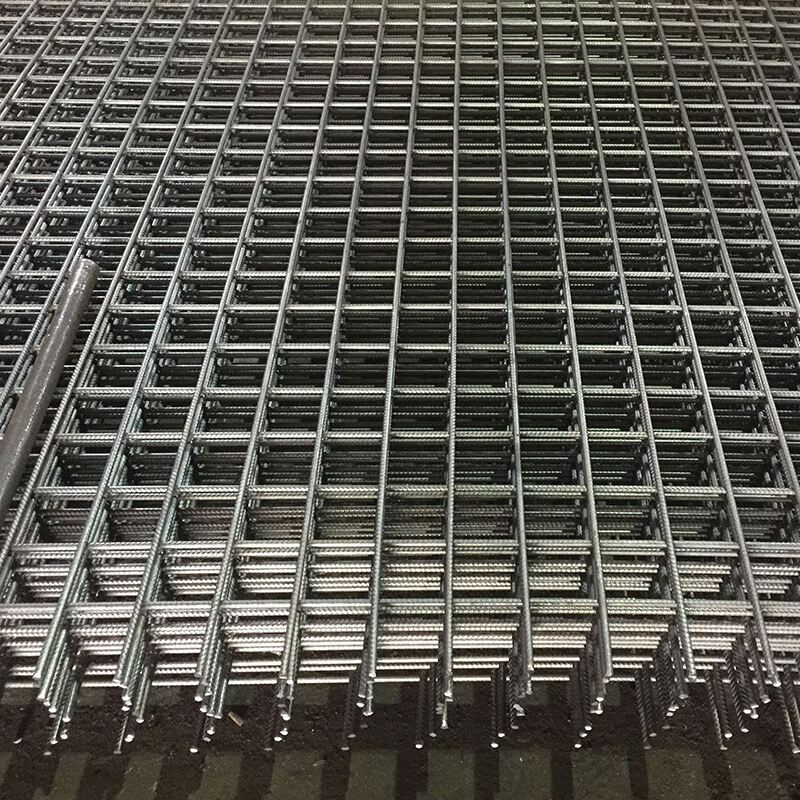

Rebar Mesh

Rebar mesh is a mesh structure material made of longitudinal and transverse steel bars through welding or binding process. It has high strength and good welding quality. Reinforcement mesh is widely used in the construction field. It can significantly improve the construction quality of steel projects, enhance the crack resistance of concrete, and speed up construction.

- Overview

- Recommended Products

Product Overview: Rebar Mesh

Rebar mesh is a mesh structure material made of longitudinal and transverse steel bars through welding or binding process. It has high strength and good welding quality. Reinforcement mesh is widely used in the construction field. It can significantly improve the construction quality of steel projects, enhance the crack resistance of concrete, and speed up construction.

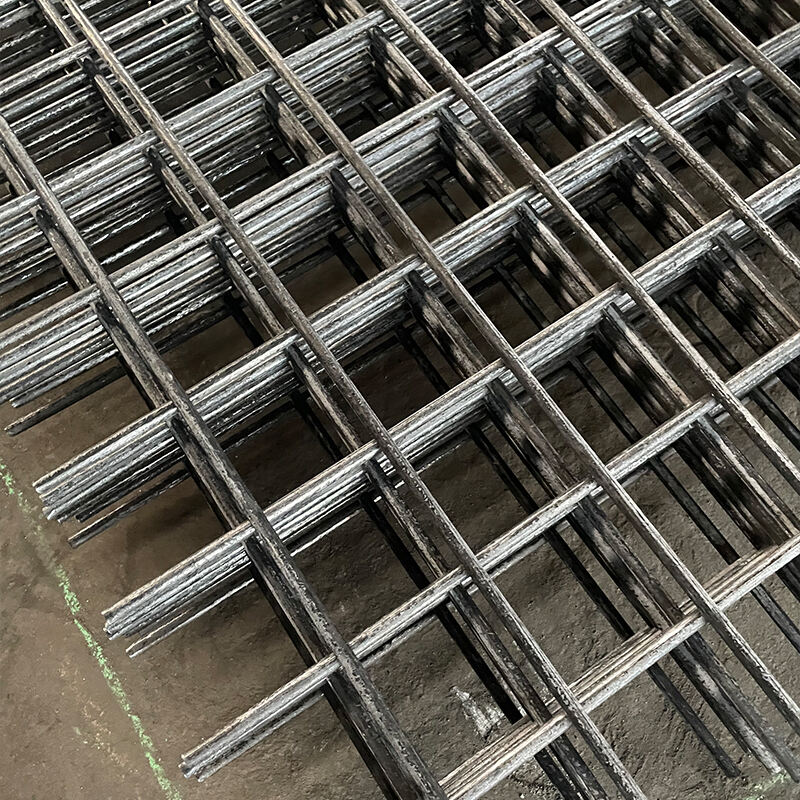

Specifications and Parameters:

| Material | The main material of rebar mesh is steel bar. Rebar is a commonly used material in construction projects, mainly used to enhance the strength and stability of concrete structures. |

| Brand | HRB400, HRB500 , B500B, A615, A706, BS4449, G3112 ... |

| Aperture | 6mm-22mm, can meet the strength requirements of different application scenarios |

| Size | 200mm×200mm, 100mm×200mm, 150mm×200mm, 100mm×100mm, 150mm×150mm, can be customized according to needs |

| Processing technology | Hot rolling welding |

| Size | Custom sizes available to fit specific project specifications |

| Compliance | Comply with relevant domestic and international standards such as ASTM, GB, JIS, etc. |

Features:

High strength and uniformity: The rebar mesh is made of high-quality steel bars, showing excellent bearing capacity and tensile strength. The uniform distribution of steel bars enables the force to be transmitted more evenly, thereby enhancing the stability of the overall structure.

Easy construction: The rebar mesh is pre-made in the factory. You only need to lay the rebar mesh as required and then pour concrete, saving 50%-70% of the working hours.

Save materials: The mesh design of the rebar mesh is reasonable, which can usually save at least 30% of the steel bars. In addition, the loss during transportation and construction is also small.

Improve the quality of the project: The characteristics of rebar mesh include high rigidity, good elasticity, uniform mesh spacing, and high strength of welding points. These advantages have jointly improved the quality of the construction project.At the same time, the rebar mesh has good adhesion to concrete and evenly distributes the load, which greatly improves the seismic performance of reinforced concrete structures and reduces the incidence of cracks.

Application scenarios:

Construction Engineering: Rebar mesh is used in construction engineering to reinforce concrete structures and improve their tensile strength and bearing capacity. It is often used to reinforce structures such as floor slabs, walls, columns, etc. to ensure the stability and safety of buildings.

Roads and bridges: Rebar mesh is used for reinforcement and support to enhance the structural strength and stability of roads and bridges and reduce the construction cost.

Tunnel engineering: Rebar mesh can be used for underground support and lining of tunnel engineering, improving the shear and bending strength of shotcrete and maintaining the stability and safety of tunnel structure.

Ground reinforcement: Rebar mesh can be used for ground reinforcement to increase its stability and anti-scouring ability, such as reinforcing earth slopes, protective walls and retaining walls.

Coal mining engineering: Rebar mesh is used for tunnel support to make the tunnel more stable and safer.

Water conservancy projects: Rebar mesh can be used for reinforcement and anti-scouring in water conservancy projects such as dams, canals, and rivers.

Environmental Engineering: Rebar mesh is used in solid waste treatment and sewage treatment to provide strong structural support and protection.

Frequently Asked Questions (FAQ):

Q: What is the lead time for custom rebar orders?

A: The delivery time is generally 1 to 3 weeks, and the specific time will vary depending on the order volume and processing complexity.

Q: What is the difference between rebar mesh and steel bars in use?

A: Rebar mesh is mainly used in concrete pavement, building foundation, etc. It can withstand large tension and pressure, improve the earthquake resistance and crack resistance of the structure, and improve the safety and durability of roads and buildings. Steel bars are mainly used in the main load-bearing parts of concrete structures to enhance the mechanical strength of concrete structures and prevent the structure from being damaged when subjected to stress.

Q: Is rebar mesh more expensive than steel bars?

A: Although the price per ton of rebar mesh is more expensive than steel bars, in actual construction, the design strength of rebar mesh is 50%-70% higher than that of Grade I steel bars. After considering some structural requirements, it can still save about 30% of steel bars. Comprehensive consideration can reduce the cost of steel bar projects by about 10%.

Q: How to maintain and preserve rebar mesh?

A: The most basic measure to maintain steel bars is to remove rust in time. Common rust removal methods include chemical rust removers, rust removers, sandblasting, pickling and manual rust removal.

Q: When purchasing rebar mesh, is it calculated based on the number of pieces or the actual weight?

A: It can be calculated by actual weight or by piece.

Q: Do you provide processing services?

A: We not only provide rebar mesh materials, but also provide cutting, punching, bending and other processing services according to customer needs. We can also recommend professional processing partners to ensure that the rebar mesh can meet the installation requirements of your project.

Contact Us:

Want to choose the right rebar mesh for your project ? Contact us now to get professional advice, detailed quotation and thoughtful service. Our professional team is looking forward to working with you.

Email: [email protected]

Tel: +86 18369600176

Choose our rebar mesh to add strength and protection to your project - here, quality and reliability go hand in hand.