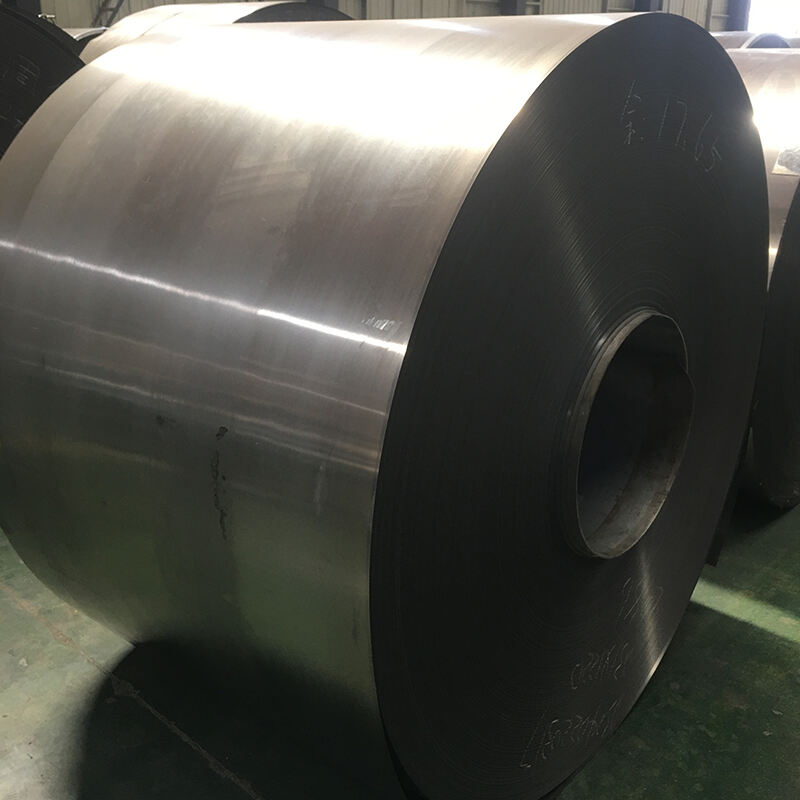

Рулон углеродистой стали

Рулон углеродной стали - это вид прокатной стали, изготовленный из обычного углеродного стального листа путем прокатки, отжига, травления и других процессов. Рулон углеродной стали обладает хорошими механическими свойствами, такими как высокая прочность, хорошая пластичность, легкость обработки и сварки, и широко используется в различных инженерных областях, таких как строительство, машиностроение, автомобили и т.д.

- Обзор

- Рекомендуемые продукты

Обзор продукта: Рулон углеродистой стали

Рулон углеродной стали - это вид прокатной стали, изготовленный из обычного углеродного стального листа путем прокатки, отжига, травления и других процессов. Рулон углеродной стали обладает хорошими механическими свойствами, такими как высокая прочность, хорошая пластичность, легкость обработки и сварки, и широко используется в различных инженерных областях, таких как строительство, машиностроение, автомобили и т.д.

Характеристики и параметры:

| Материал | Сплав железа с углеродом, содержание которого находится в пределах от 0,0218% до 2,11%, также известен как углеродистая сталь. Обычно содержит небольшие количества кремния, марганца, серы и фосфора. В зависимости от содержания углерода его можно разделить на простую углеродистую сталь, низколегированную высокопрочную сталь и высокougлеродистую сталь. |

| Бренд | Q195, Q235, Q355, A36, A573, S235, DC01, DC04... |

| Толщина | 0,5мм-20мм, может удовлетворять требованиям прочности для различных прикладных сценариев |

| Ширина | 600 мм - 2500 мм, подходит для различных технологий производства и обработки |

| Технология обработки | Горячекатаный, холоднокатаный |

| Размер | Доступны пользовательские размеры для соответствия спецификациям конкретного проекта |

| Стандарт | Строго следуют международным и национальным авторитетным стандартам, таким как ASTM, JIS, EN, DIN, GB и др. |

Особенности:

Отличные механические свойства: Углеродистые стальные катанки обладают хорошими механическими и обрабатывающими свойствами и подходят для различных инженерных областей. Они имеют высокую прочность, хорошую вязкость и сильное сопротивление коррозии. Подходят для выдерживания больших нагрузок и могут использоваться в различных суровых условиях.

Хорошая производительность обработки: Коил из углеродистой стали получают путем горячей прокатки низкоуглеродистой стали, а затем сворачивают его. Его химический состав должен соответствовать соответствующим стандартам. Низкоуглеродистая сталь обладает высокой прочностью и пластичностью, а также отличными сварочными характеристиками.

Широкий диапазон сфер применения: Углеродистые коилы с разными технологиями, составами и толщинами имеют различные характеристики и могут широко применяться в строительстве, машиностроении, автомобилестроении и других отраслях.

Низкая экономическая стоимость: Качественные углеродистые коилы обладают хорошим блеском и ровностью, на поверхности отсутствуют трещины, пузыри и другие дефекты, при этом они относительно недорогие. Это экономичный и практичный металлический материал.

Сценарии применения:

Строительство: В строительной индустрии углеродистые стальные катанки широко используются для изготовления различных несущих деталей и компонентов. Их высокая прочность и хорошая пластичность делают углеродистые стальные катанки идеальным материалом для несущих строительных конструкций. Кроме того, углеродистые стальные катанки также используются для производства инфраструктуры, такой как мосты и защитные ограждения автострад, обеспечивая плавное и безопасное движение транспорта.

Производство: Из них можно изготавливать детали различной формы и размера для удовлетворения потребностей в производстве машинного оборудования. Инструменты, такие как ножи и пресс-формы, изготовленные из углеродистых стальных катанок, не только повышают производительность, но и обеспечивают точность и качество продукции.

Автомобильная промышленность: От кузова автомобиля до двигателя, от шасси до деталей, углеродистые стальные катанки повсеместно применяются в автомобилестроении. Их отличная прочность и коррозионная стойкость делают автомобиль более долговечным и обеспечивают безопасность водителя.

Энергетическая отрасль: Углеродистые стальные катанки используются для производства нефтегазовых трубопроводов, гарантируя безопасную транспортировку энергоносителей.

Химическая промышленность: Углеродистая стальная катушка является ключевым материалом для производства химических реакторов и резервуаров, а также для транспортировки низкодавленных жидкостей.

Часто задаваемые вопросы (FAQ):

В: Каков срок выполнения заказа на индивидуальную катушку из углеродной стали?

А: Срок доставки обычно составляет от 1 до 3 недель, в зависимости от объема заказа и сложности обработки.

В: Можно ли использовать катушки из углеродной стали в качестве конструктивных компонентов?

А: У углеродной стальной рулонной стали также отличные механические свойства. Она обладает высокой прочностью, твердостью и ударной вязкостью, и может выдерживать большие нагрузки и удары. Углеродная стальная рулонная сталь часто используется для изготовления конструктивных рам и компонентов, а также различных механических частей и компонентов. Ее отличная прочность и коррозионная стойкость могут удовлетворить требования к стабильности и долговечности.

В: Есть ли цветовые варианты для оцинкованных катушек?

А: Хотя оцинкованный рулон сам по себе серебристо-белый, он может предложить различные варианты цветов через последующий процесс покраски, чтобы удовлетворить ваши дизайнерские требования.

В: Как ухаживать и заботиться о катушках из углеродной стали?

А: Самая основная мера по уходу за углеродными стальными листами - это регулярная их очистка. После использования их следует вовремя промыть теплой водой, затем вытереть насухо чистой тканью и хранить в сухом месте.

Q: Какие методы обработки поверхности доступны для углеродных стальных пластин?

А: Мы предоставляем различные методы обработки поверхности, такие как термическая обработка, которая может изменить организационную структуру стали, улучшить твердость и прочность; травление может удалить оксидную пленку и загрязнения с поверхности, улучшить качество и чистоту поверхности; оцинковка может улучшить коррозионную стойкость и стойкость к окислению стали и т.д., чтобы удовлетворить потребности различных клиентов.

Q: Вы предоставляете услуги по обработке?

А: Мы не только предоставляем материалы в виде катушек из углеродной стали, но также предоставляем услуги по резке, пробивке, гибке и другим видам обработки в соответствии с потребностями клиентов. Мы также можем порекомендовать профессиональных партнеров по обработке, чтобы гарантировать, что катушки из углеродной стали могут соответствовать требованиям вашего проекта по установке.

Свяжитесь с нами:

Хотите выбрать правильную катушку из углеродной стали для вашего проекта? Свяжитесь с нами сейчас, чтобы получить профессиональные советы, подробную смету и внимательное обслуживание. Наша профессиональная команда с нетерпением ждет возможности работать с вами.

Электронная почта: [email protected]

Телефон: +86 18369600176

Добавьте прочность и защиту вашему проекту, выбрав наши катушки из углеродной стали - где качество и надежность идут рука об руку.