- Overview

- Related Products

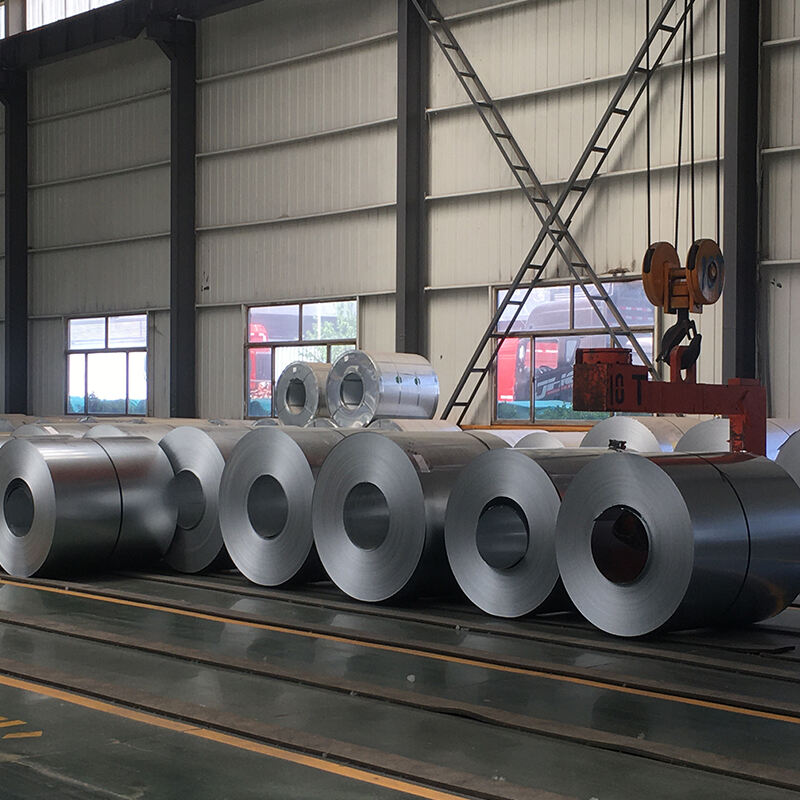

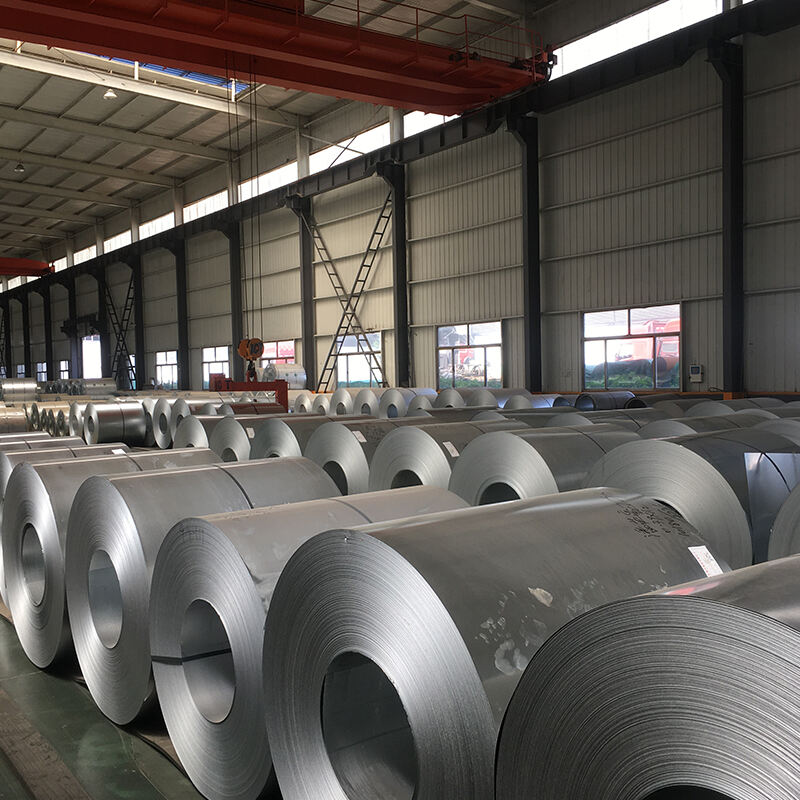

Product Overview: Galvanized coil

Galvanized coil is a steel coil treated by a special galvanized process, which has excellent corrosion resistance and durability. It uses high-quality cold-rolled or hot-rolled steel plates as the substrate, and forms a uniform zinc layer on its surface through the hot-dip galvanizing process to enhance the protective performance. Galvanized coil is widely used in construction, industrial manufacturing, home appliances, transportation and other fields.

Specifications and Parameters:

Substrate: Select high quality cold-rolled or hot-dip galvanized steel sheet to ensure the basic quality of the product

Thickness: 0.13-3.0mm, can be customized according to different application scenarios

Galvanized layer weight: 30-275g/m², provide different thickness of zinc layer to meet different protection needs

Size customization: According to the project design, precise cutting and customization can be made to achieve seamless docking

Standard certification: strictly follow ASTM, JIS, EN, DIN, GB and other international and domestic authoritative standards

Product Features:

Corrosion resistance: Zinc layer can effectively prevent steel rust, prolong the service life

Durability: The high strength steel plate and uniform zinc layer enable it to maintain performance even in harsh environments

Cost-effectiveness: Under the premise of ensuring quality, achieve cost optimization and escort the project budget

Easy processing: good processing performance, easy to shear, stamping, bending and other operations, to adapt to the changing processing needs

Application Scenarios:

Construction works: Used for building exterior walls, roofs, awnings and other parts to provide solid protection and beautiful appearance

Industrial manufacturing: suitable for manufacturing industrial plants, warehouses, mechanical parts, etc., to enhance the durability of the structure

Home appliance industry: Used to manufacture home appliance shell, components, etc., to improve the durability and beauty of products

Transportation: Suitable for the manufacture of vehicles such as cars and trains, providing lightweight and corrosion-resistant solutions

Frequently Asked Questions (FAQ):

Q: How long is the lead time for custom galvanized coil orders?

A: Delivery time is usually 1 to 2 weeks, depending on order volume and processing complexity.

Q: Can galvanized coils be used in projects under extreme environmental conditions?

A: Yes, our galvanized coils are designed to withstand extreme environmental conditions, including high temperatures, cold, strong winds and corrosive atmospheres.

Q: Do galvanized rolls have color options?

A: Although the galvanized coil itself is silver white, a variety of color options can be provided through subsequent painting processes to meet your design requirements.

Q: How to maintain and clean galvanized coil?

A: The maintenance of galvanized coil is relatively simple. Regular cleaning with a mild cleaner and water will keep it looking like new. Avoid abrasive cleaners to prevent scratching.

Q: What are the benefits of the zinc layer on the galvanized roll?

A: The zinc layer has excellent corrosion resistance and can form a protective film on the surface of the steel plate to prevent rust and effectively extend the service life of the product.

Q: Do you offer processing services?

A: Although we mainly supply galvanized coils, we can provide cutting, stamping, bending and other processing services to ensure that the product meets your installation requirements.

Contact Us:

Want to choose the right galvanized roll for your project? Contact us today for professional advice, detailed quotes and attentive service. Our team of professionals look forward to working with you.

E-mail: [email protected]

Tel: +86 15269108961

Choose our galvanised rolls to add robustness and protection to your work - where quality goes hand in hand with reliability.